What Is Cantilever Racking?

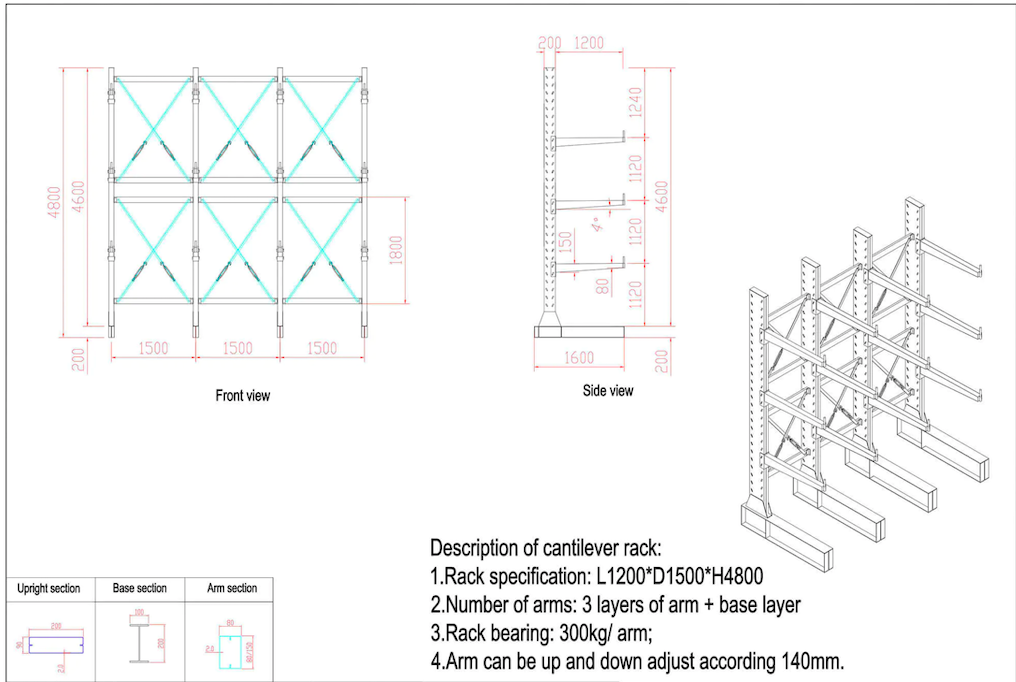

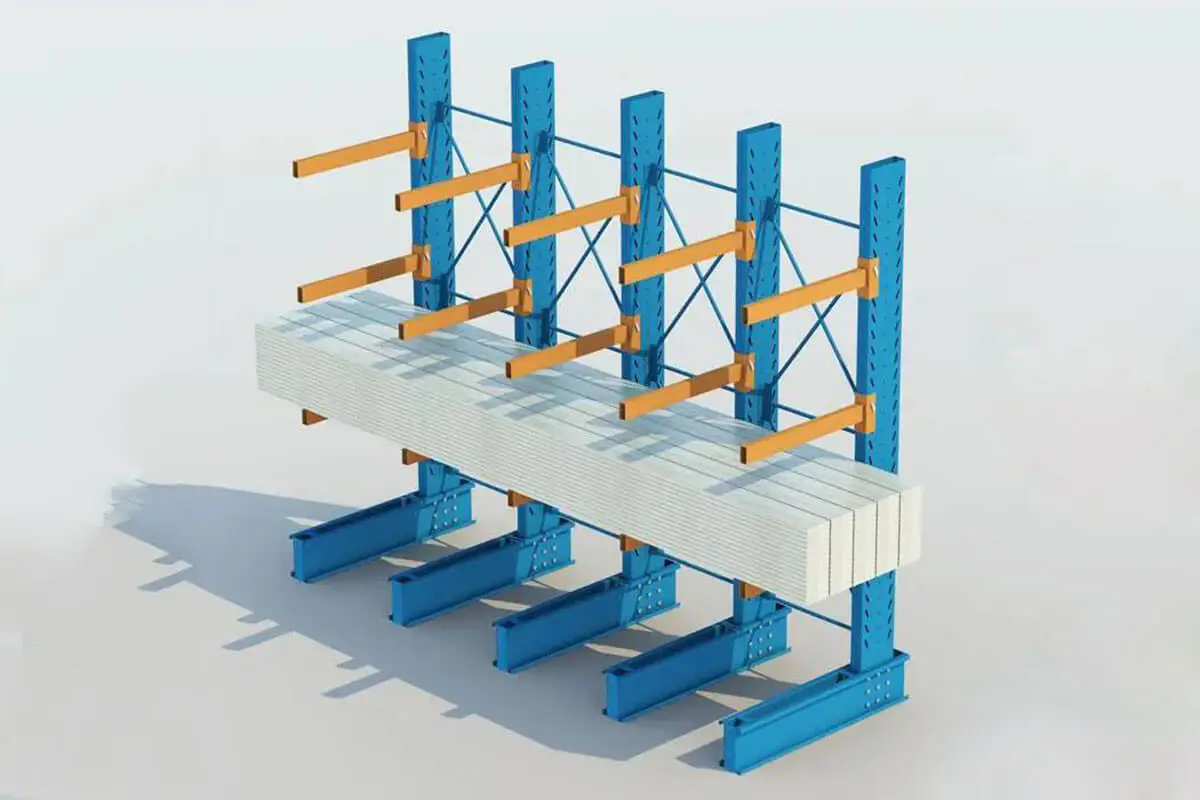

Cantilever Racking is a kind of warehouse racking,mainly composed of columns,cantilever arms,horizantal and diagonal bracing ect.It is usually divided into single-sided cantilever racks and double-sided cantilever racks.Cantilever rack system is often used to store long,ring,plate and irregular shaped goods,such as steel pipes,plywood,car etc.The load capacity of cantilever racks is usually in the range of 200kg-1500kg per arm,and the load capacity and number of levels can be designed and customized accoding to the specific storage need of customers.

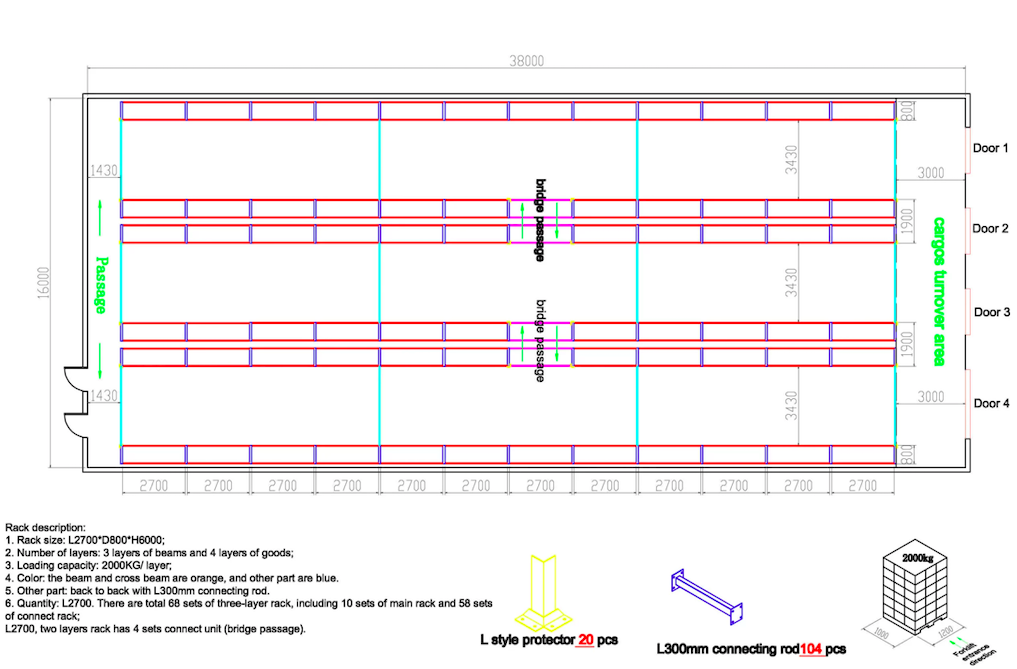

Free Design Drawings For You

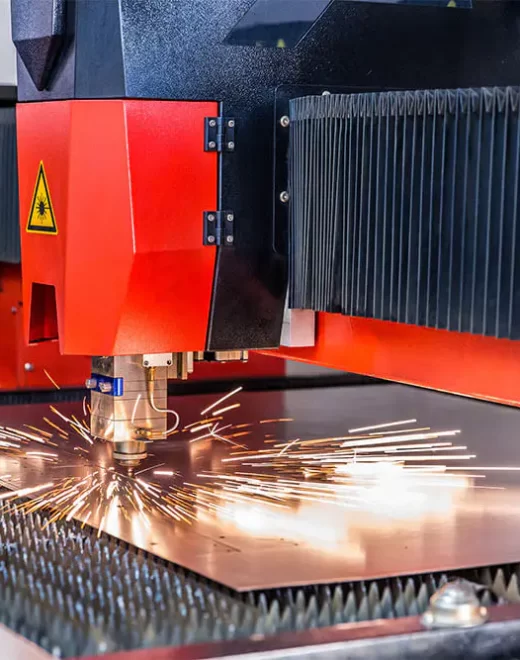

The Main Production Process Of Cantilever Racking

Our Products Are Packaged In The Following Ways

Air Bubble Film

Pallet Packaging

Wooden Case

Carton Box