Mezzanine Floor

What Is Mezzanine Floor?

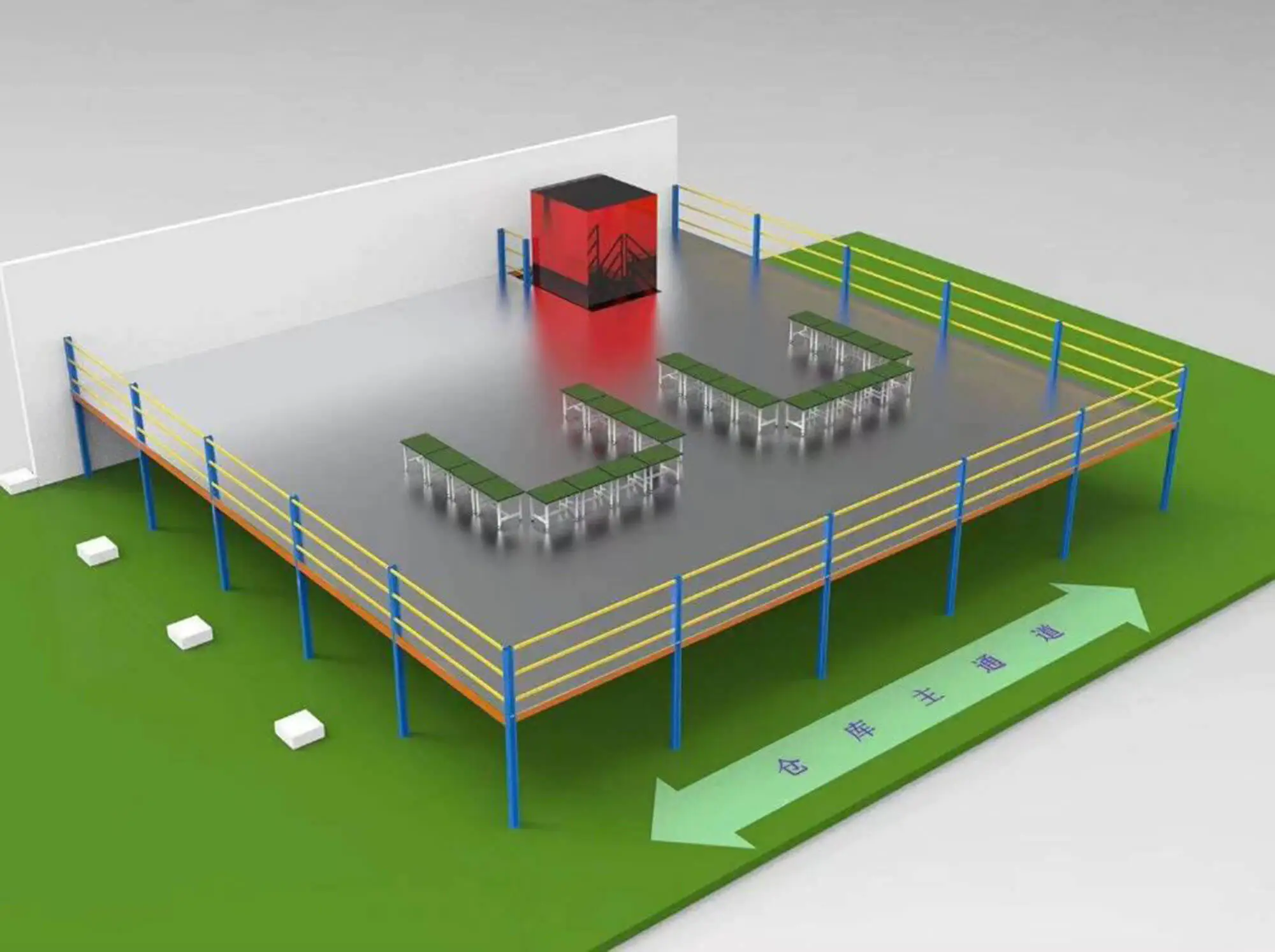

Mezzanine Floor is platform sections that are installed between the floor and ceiling and have multiple uses in warehouse operations.They are excellent for increasing storage space and work space in warehouse facility.Mezzanine floor is a platform built on the existing work site or warehouse to increase warehouse storage space.It can be made of two or three layers of mezzanine,suitble for multi-species large or multi-species small batches of goods,manual access to goods.The goods are usually sent to the second and third floors by forklift,hydrauliclifting platform or freight elevator,and then sent to a certain position by light trolley or hydraulic pallet truck.Mezzanine platforms are freestanding steel structures installed and designed the suit the layout of the warehouse.Most mezzanines system can be designed around existing columns,machinery,windows and sprinkler systems,In most cases,many business use steel mezzanines as office space,to beds,employee break rooms or picking operations.Wherever your facility needs more floor space,warehouse mezzanine systems are an excellent solution.

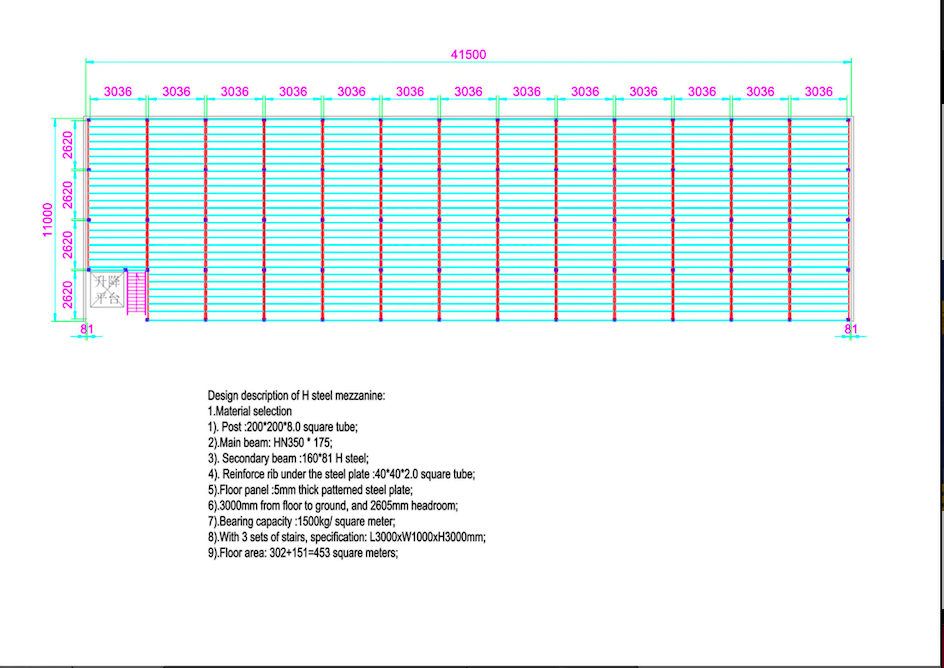

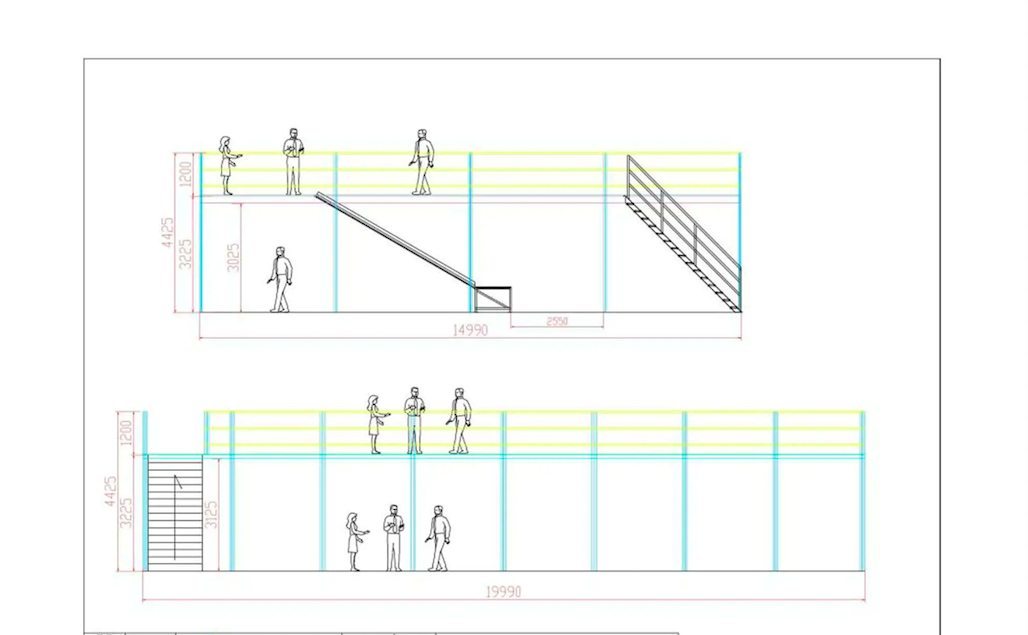

Free Design Drawings For You

The Main Production Process Of Selective Pallet Racks

Our Products Are Packaged In The Following Ways

Air Bubble Film

Pallet Packaging

Wooden Case

Carton Box