WHAT WE OFFER

High-Quality Materials

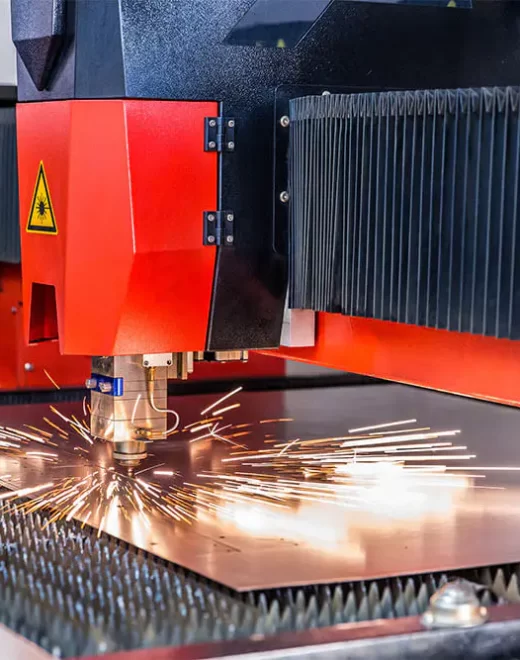

Exquisite Technology

Full Service

Selective Pallet Racking System

What Is Selective Pallet Racking?

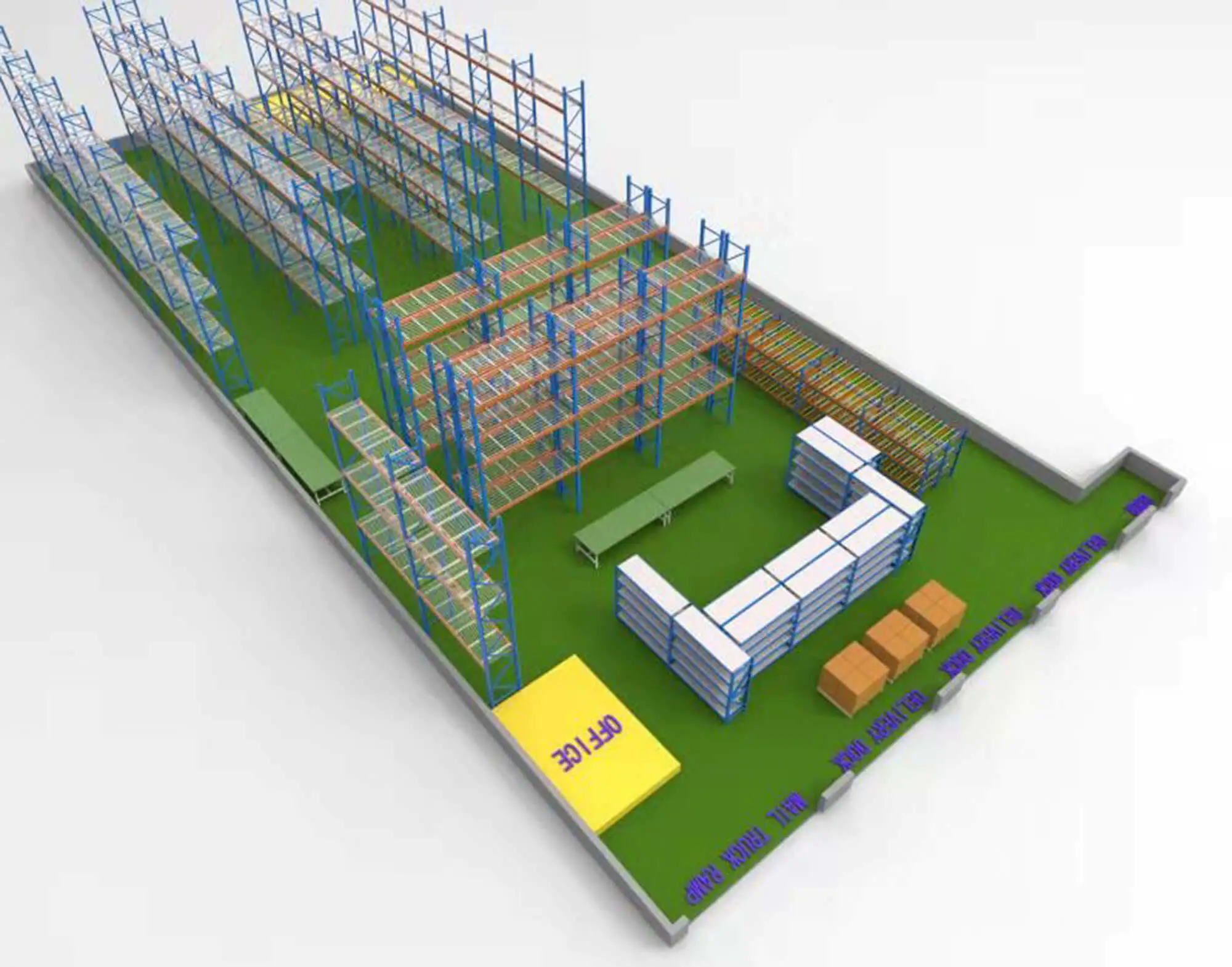

Selective pallet rack also named beam rack or heavy-duty rack, is very common in the various kinds of warehouse racks. The main components are an upright frame+beam, the structure is concise and effective. This is the most diversified warehouse rack and works with forklifts for pallets up and down. It is wildly used by most enterprises. Selective pallet racks wildly use many manufacturers, E-commerce warehouses, third logistics and distribution centers, etc. It is suitable for many kinds of small bulk items, but also suitable for a small variety of items. Learn more about the advantages of selective pallet racks.

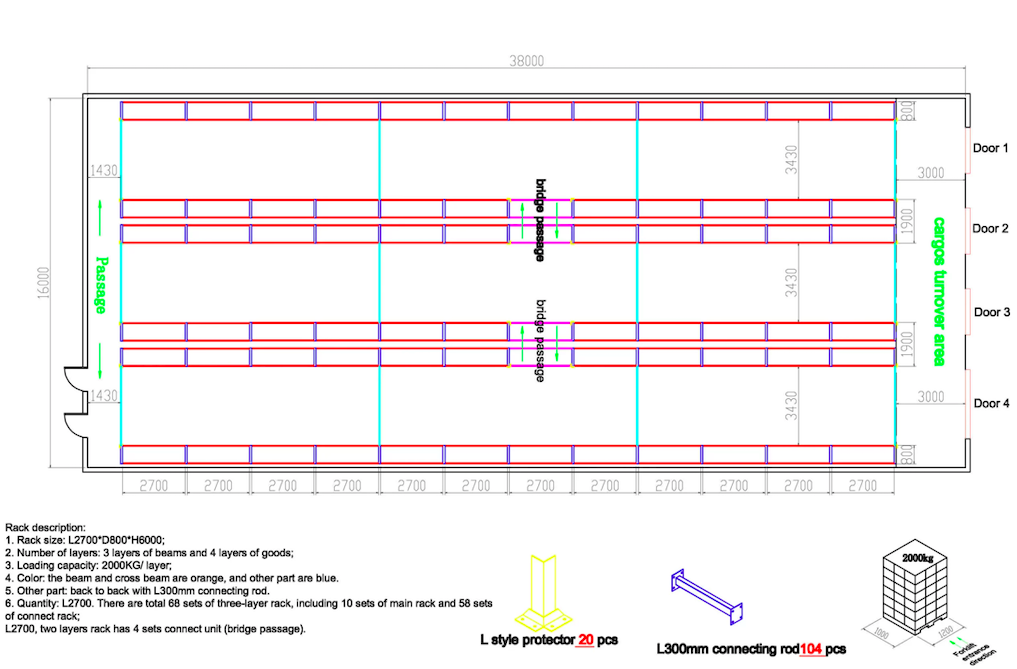

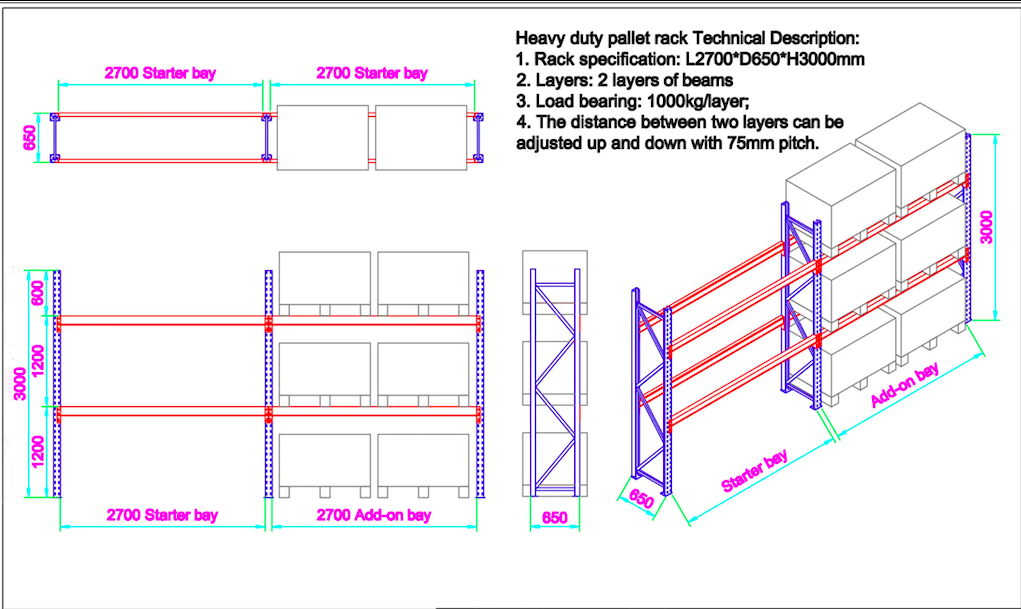

Free Design Drawings For You

The Main Production Process Of Selective Pallet Racks

Our Products Are Packaged In The Following Ways

Air Bubble Film

Pallet Packaging

Wooden Case

Carton Box