Doble deep Pallet Racking

Tuobang Storage Equipment Company is a leading double deep racking manufacturer in China,with over 10 years of double deep racking manufacturing experience,we can provide you with double deep pallet racking customization and installation service,Click the”Quick Quote”below to get an instant quote on double deep racking.

What Is Double Deep Pallet Racking?

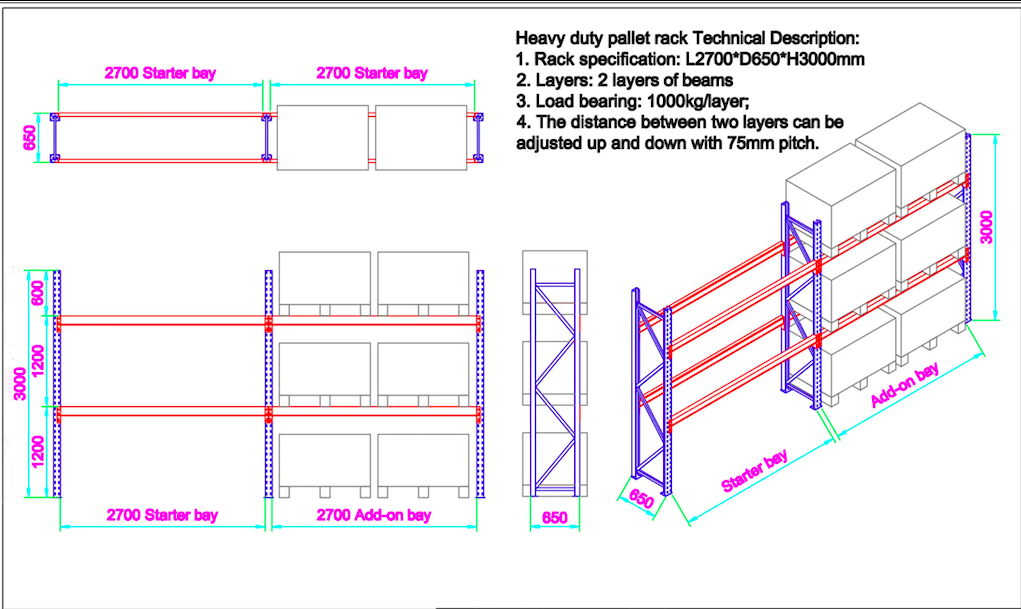

Double Deep Pallet Racking is a racking storage system derived from heavy duty pallet racking,It’s simple construction and high storage capacity reduce the number of aisles required by storing two or more deep pallets,allowing for higher storage density while still allowing operators to access each storage bay easily and relatively quickly.Compared to normal beam pallet racking ,double deep racking doubles the storage capacity,effectively relieving storage needs that cannot be met by normal pallet racking.Since there are more than two bays of goods on the depth of the racking,ordinary forklift trucks can no longer complete the access to the goods on double deep pallet racking,and special double deep racking forklift truck with telescopic forks are required to carry out the access work.

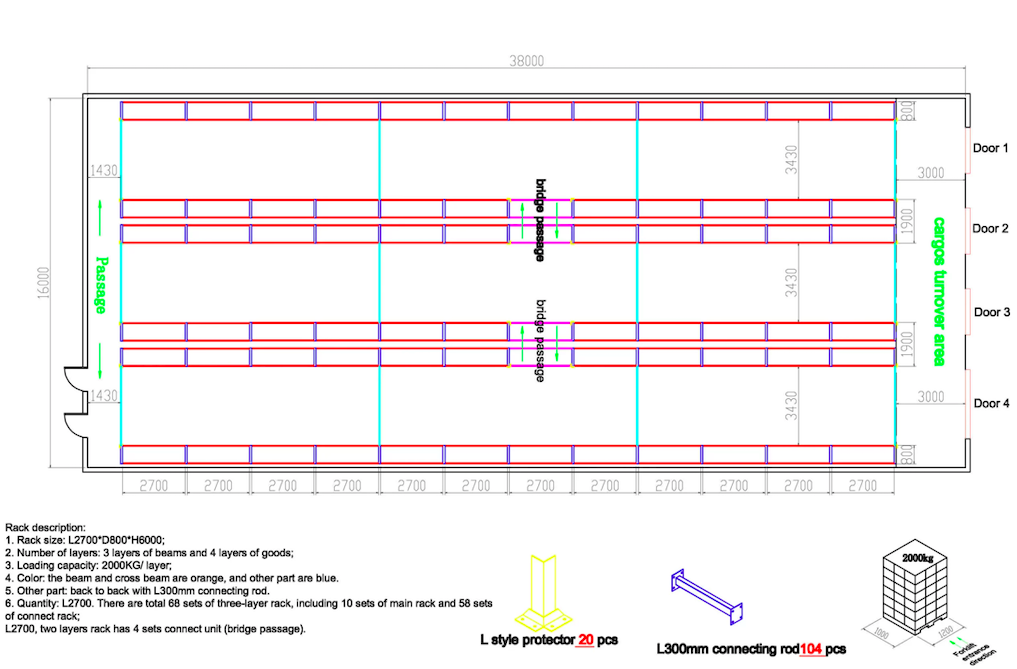

Free Design Drawings For You

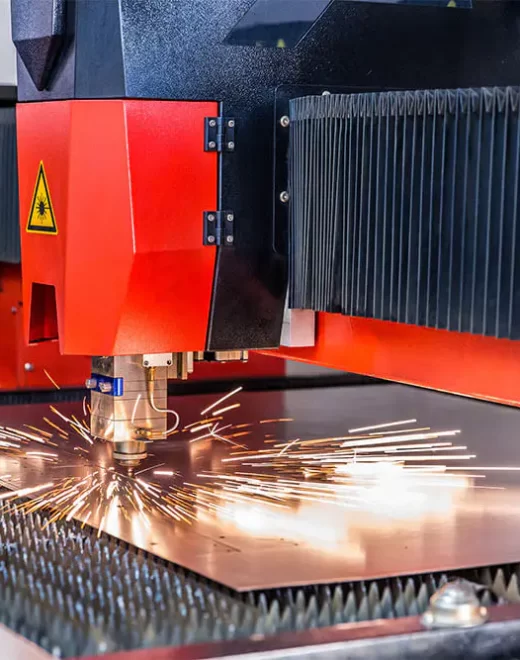

The Main Production Process Of Selective Pallet Racks

Our Products Are Packaged In The Following Ways

Air Bubble Film

Pallet Packaging

Wooden Case

Carton Box