WHAT WE OFFER

High-Quality Materials

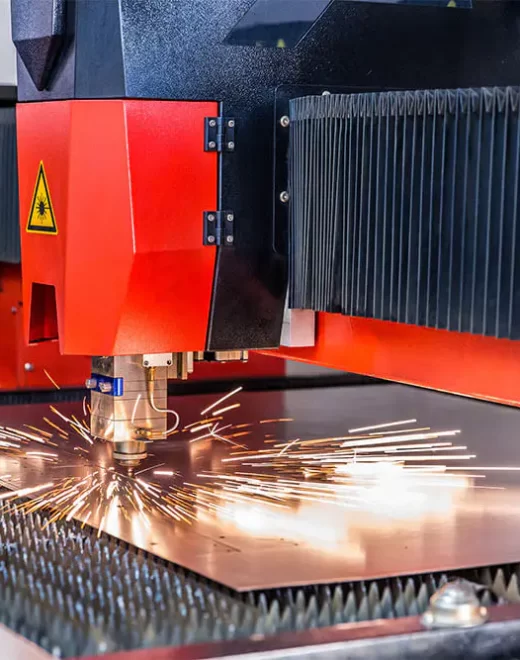

Exquisite Technology

Full Service

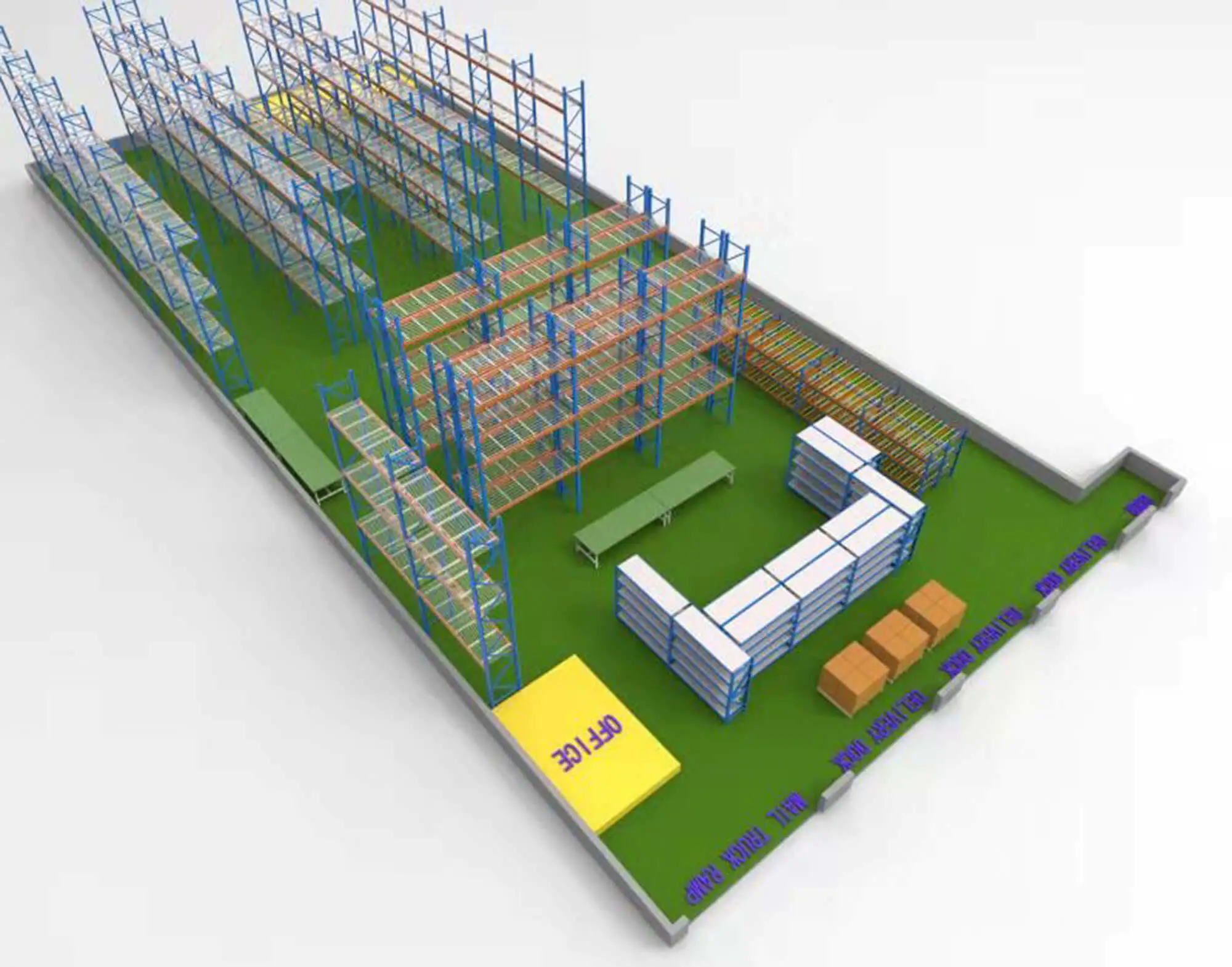

Industrial Mezzanine Structural Steel Mezzanine Floor Supplier

What Is Structural Steel Mezzanine?

Structural steel Mezzanine also called steel mezzanine floor.The most important feature of modern steel mezzanine structural is its fully assembled structural ,which is flexible in design and has certain anti-vibration capability compared with general storage equipment .It is more widely used in modern storage.

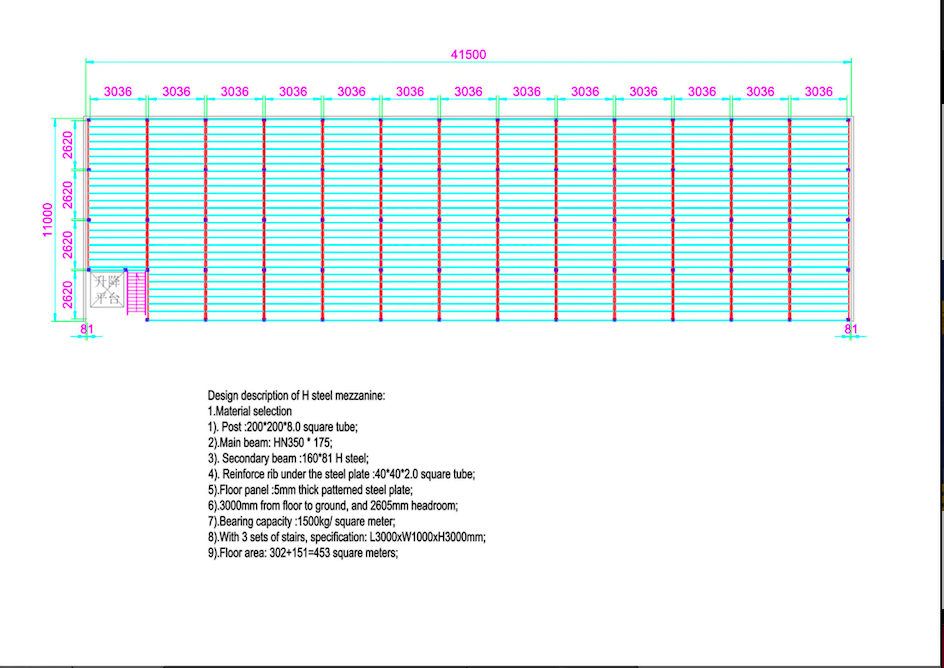

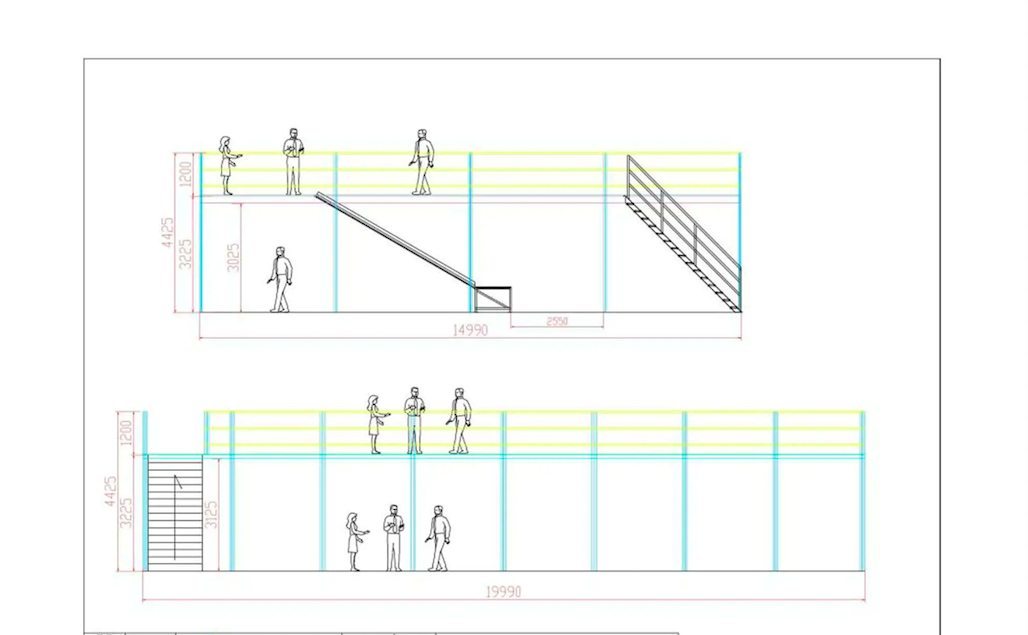

Free Design Drawings For You

The Main Production Process Of Selective Pallet Racks

Our Products Are Packaged In The Following Ways

Air Bubble Film

Pallet Packaging

Wooden Case

Carton Box