WHAT WE OFFER

High-Quality Materials

Exquisite Technology

Full Service

Medium duty Rack

What Is Medium Duty Rack?

Medium Duty Rack are made of welded upright frame and “P”beams, which are simple and easy to assemble.It is suitable for storing goods of small size and weight,and the medium duty rack can also be used as household racks.The advantage of medium duty rack is that it is easy to assemble.Medium duty rack is designed for easy assembly, and you can easily adjust the number and height of racks according to the volume and weight of goods to meet your different storage needs.Compared to selective pallet racking ,medium duty rack is cheaper, but the disadvantage of medium duty rack is that it is larger, so usually transportation cost of medium duty rack is higher.

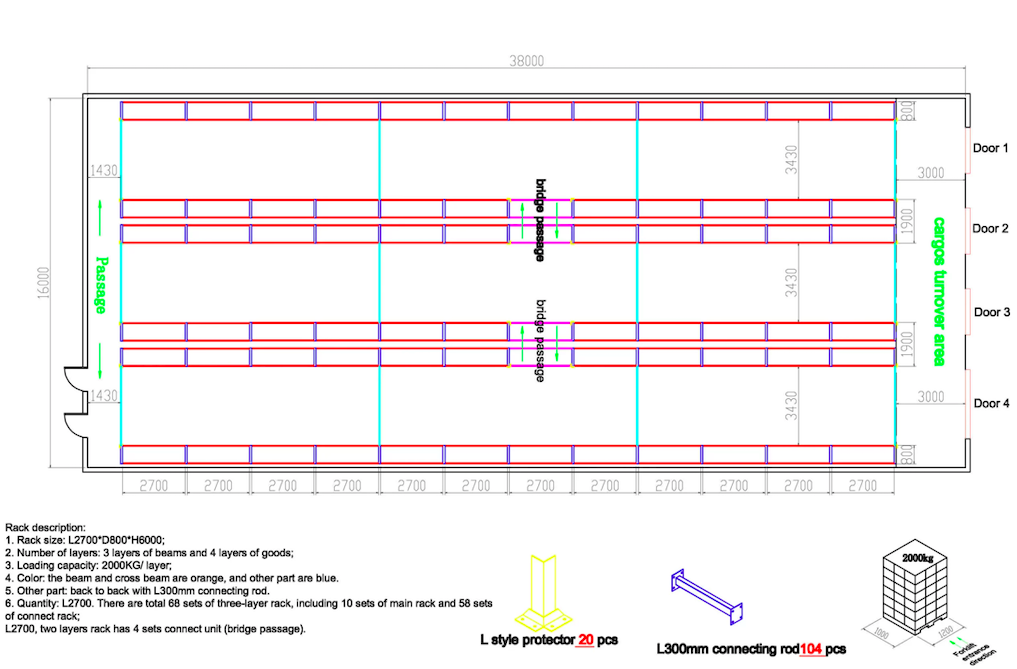

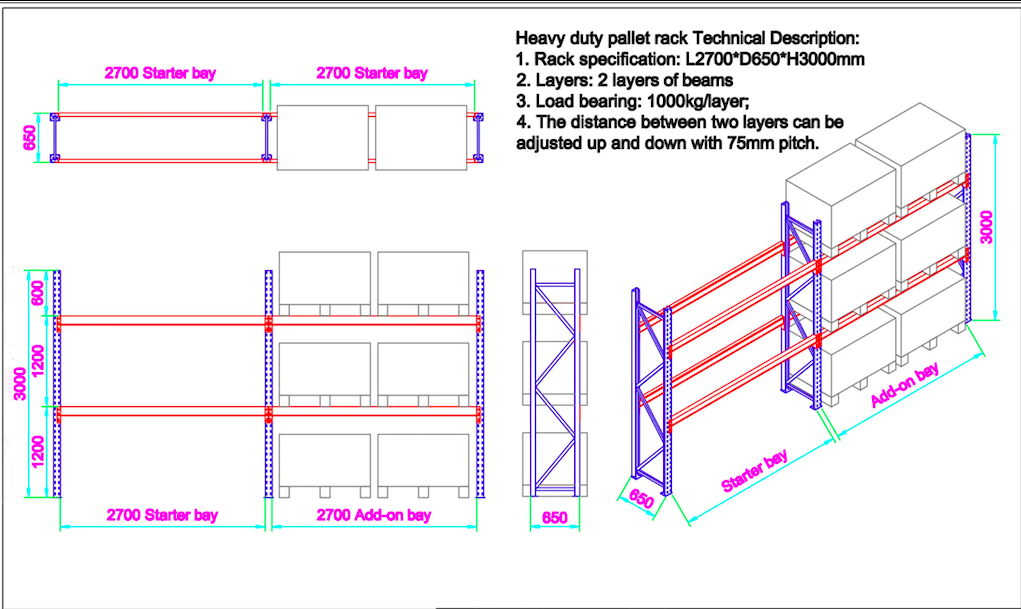

Free Design Drawings For You

The Main Production Process Of Medium Duty Rack

Our Products Are Packaged In The Following Ways

Air Bubble Film

Pallet Packaging

Wooden Case

Carton Box