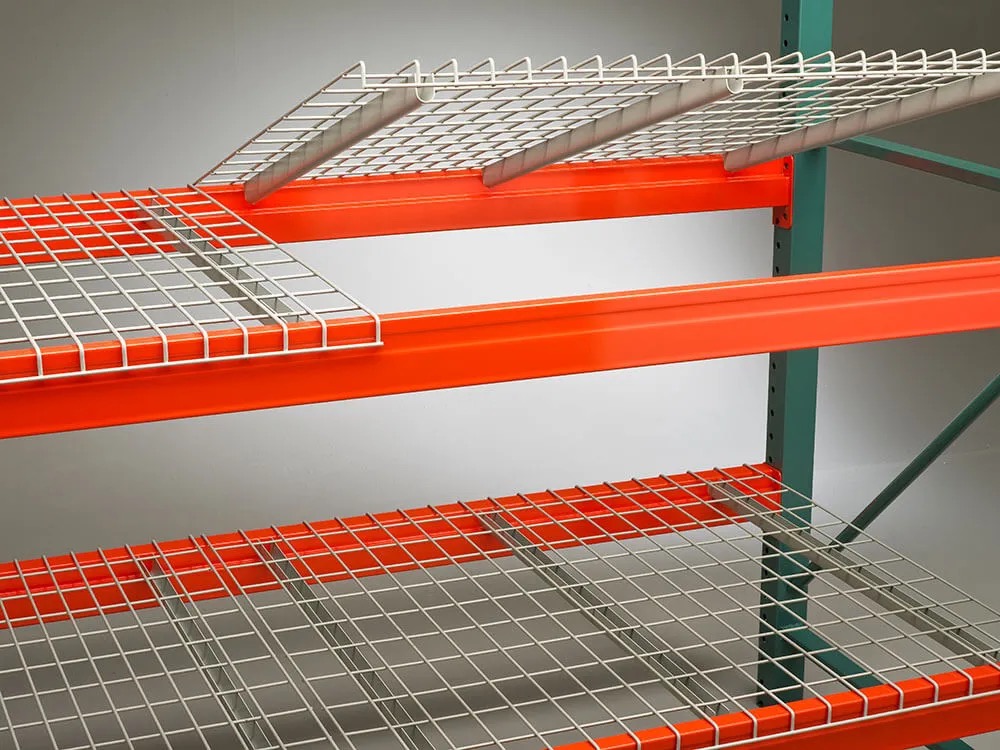

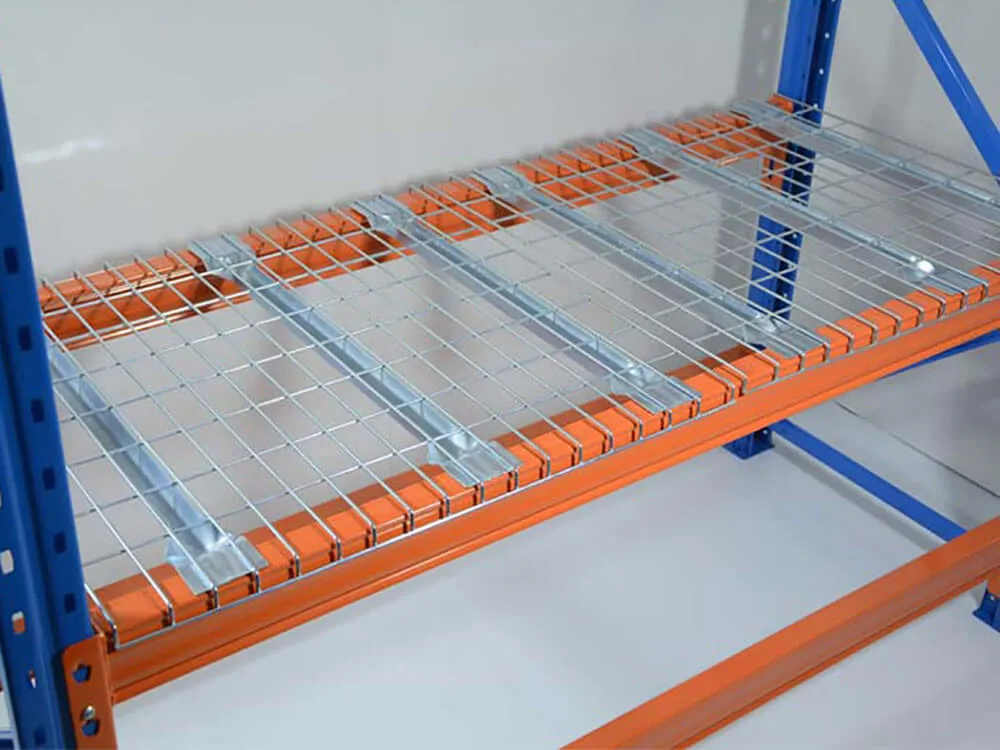

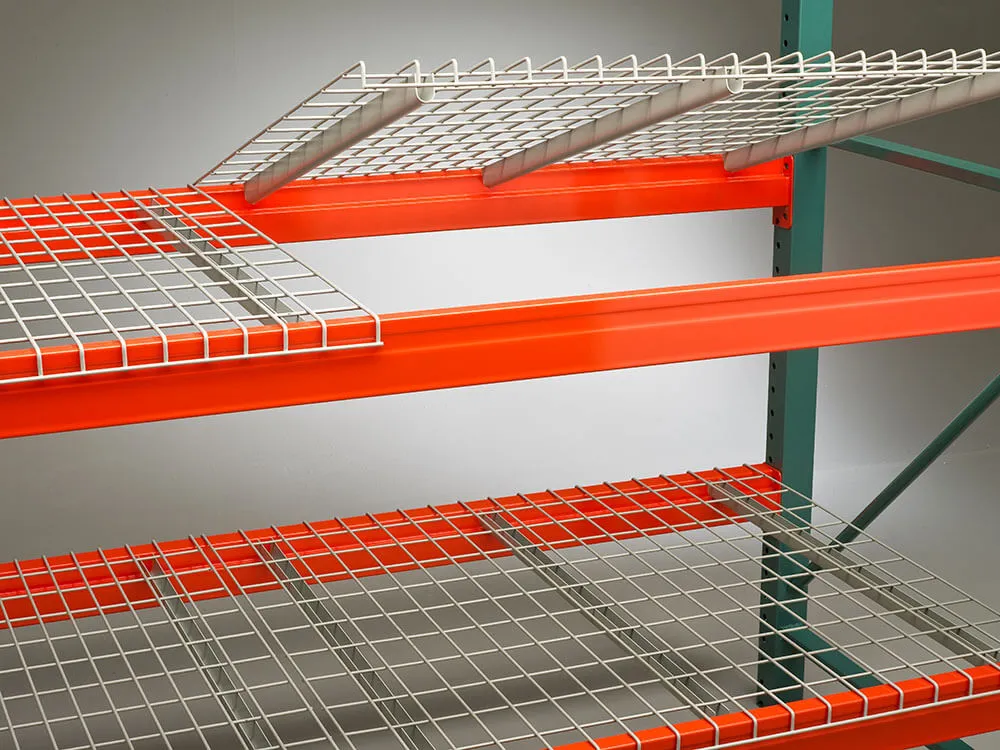

Wire Mesh Decking

What Is Wire Mesh Decking?

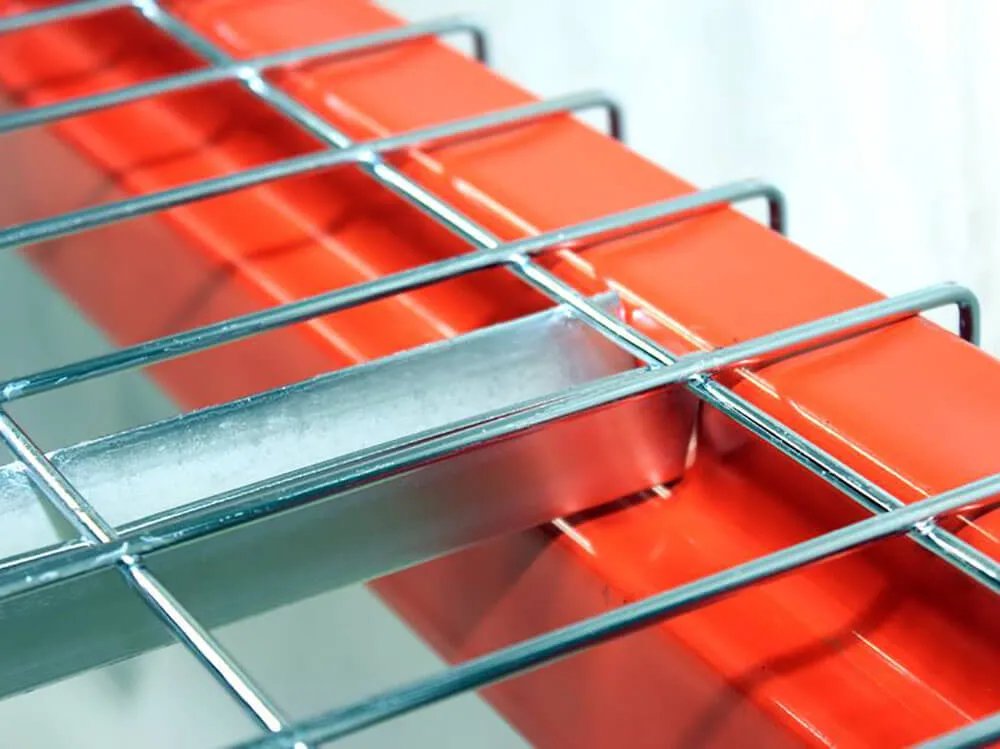

Wire Mesh Decking is made of high quality cold drawn wire spay welded to form a mesh with 50*50 or 50*100 holes,reinforced with welded bars at the bottom,and bent on both sides to be placed on top of the racking beams to ensure the safety of the goods stored.The general load capacity is 1000kg per piece,and the maximum load capacity can be 3000kg per piece .Pallet rack wire mesh decking helps to prevent cargo from falling from high places,which effectively protects the safety of warehouse workers.

The Main Production Process Of Wire Mesh Decking

Our Products Are Packaged In The Following Ways

Air Bubble Film

Pallet Packaging

Wooden Case

Carton Box