Mezzanine Racking

What Is Mezzanine Racking?

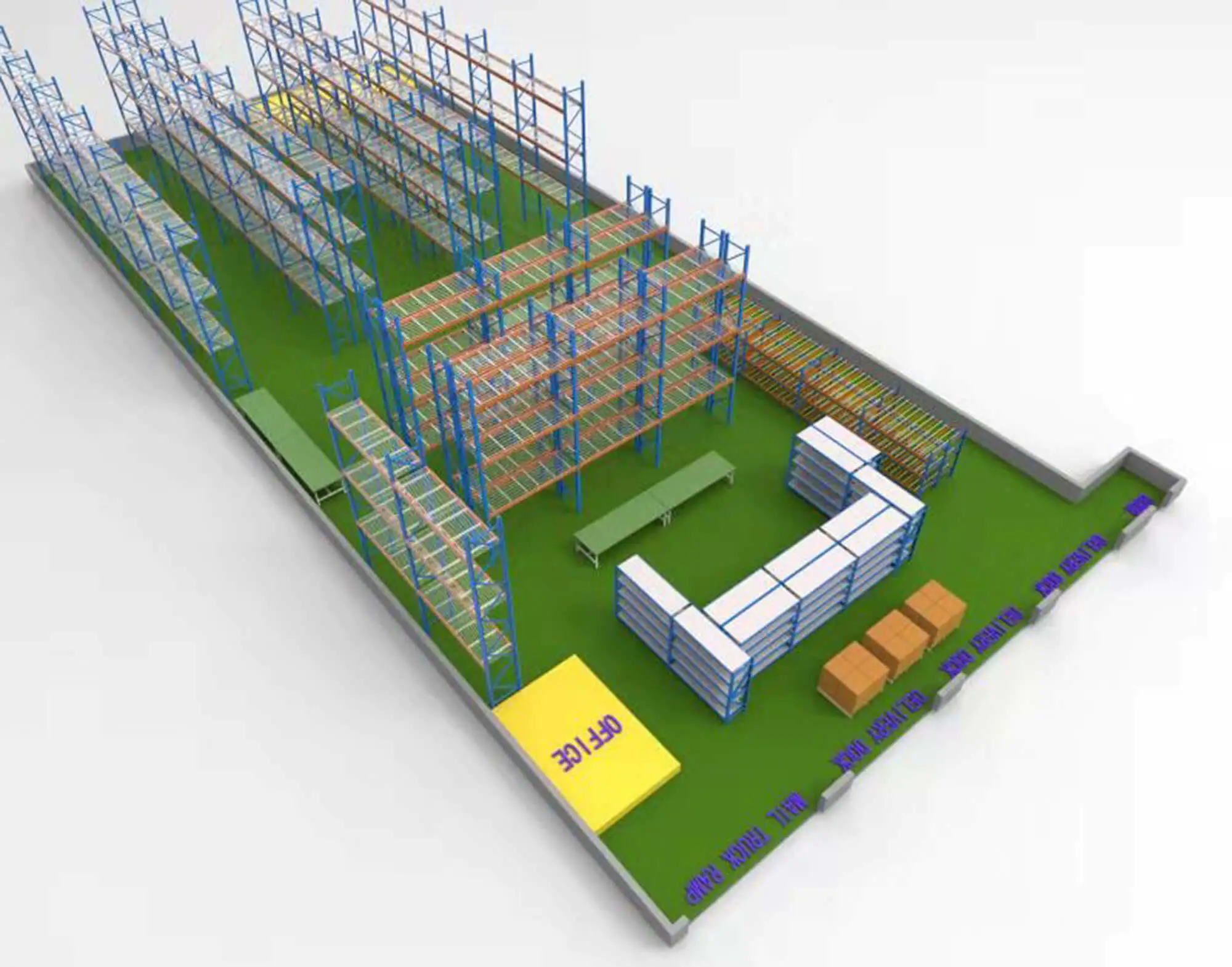

Mezzanine Racking also called pallet racking mezzanine or rack-supported mezzanine 。The mezzanine racking system is to build on intermediate mezzanine on the existing workplace or rack to increase the storage space.Pallet Racking mezzanine can be a two-level mezzanine or a three-level mezzanine, it is suitable for accessing some lightweight and small volume goods ,and it is suitable for multi-variety high volume or multi-variety small volume goods.It is necessary to access the goods by hand, the goods are usually sent to the second or third floor by forklift, hydraulic lift or elevator, then by light trolley or hydraulic pallet truck to a certain location.Mezzanine rack, usually using medium duty rack or heavy duty racks as the main body and floor support (according to the total weight of the unit racks to determine the choice of racks),the floor panel is usually selected cold -rolled steel plate, patterned steel plate or steel gate.Mezzanine racking system has more applications in the field of auto parts, light industry ,electronics, clothing and other industries.

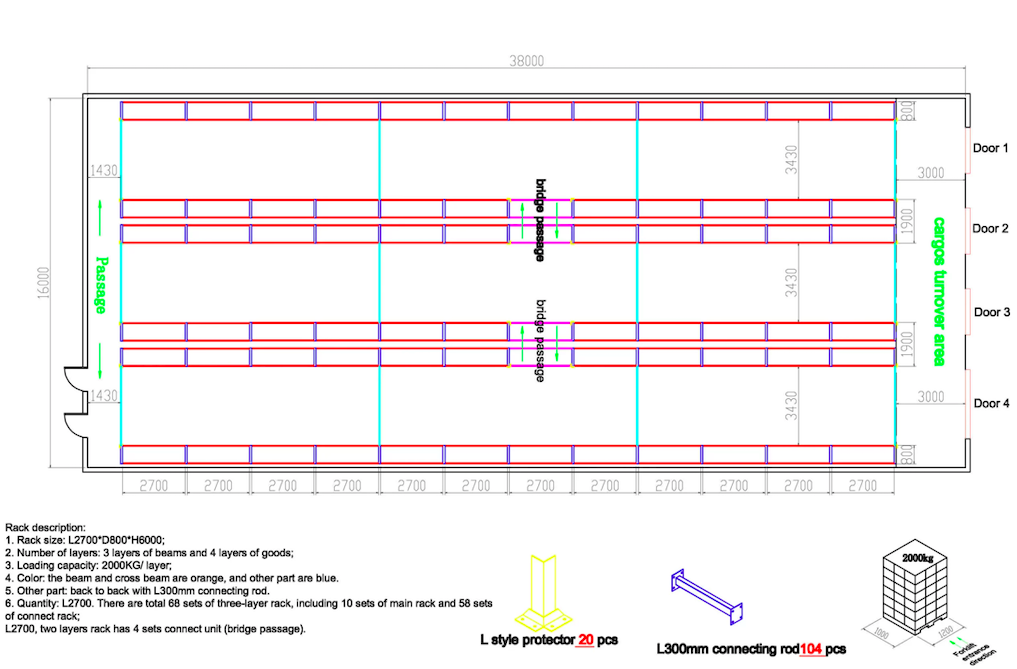

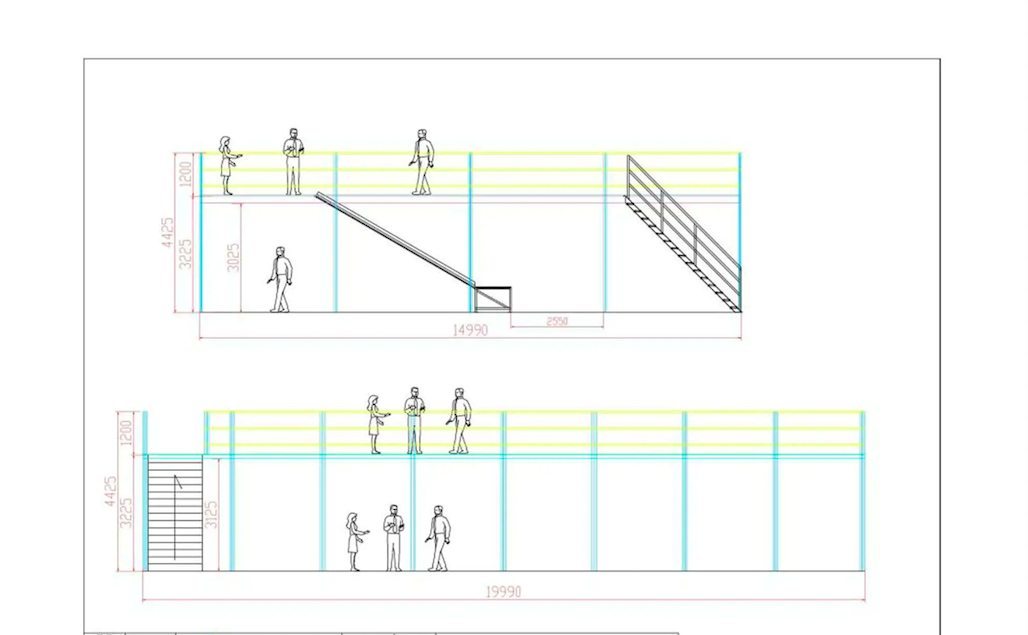

Free Design Drawings For You

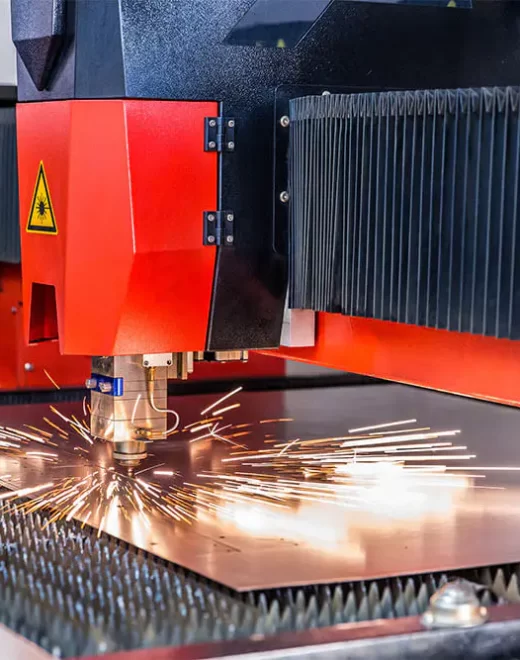

The Main Production Process Of Selective Pallet Racks

Our Products Are Packaged In The Following Ways

Air Bubble Film

Pallet Packaging

Wooden Case

Carton Box